Motor cable drums are used as a current supply to mobile current-using equipment for automatic winding of flexible electrical cables.

Motor cable drums are produced with the ability to wind 10 to 200 m cables, with the number of slip rings - 2 to 15, and the operating current up to 300 A.

| The type | The number of slip rings, pcs. | The max permissible current on the ring, A | The cable length, m | Drive power, kW |

| DKB-M-3-160-10-U1 | 3 | 160 | 10 | 0,1 |

| DKB-M-3-160-20-U1 | 3 | 160 | 20 | 0.25 |

| DKB-M-5-160-10-U1 | 5 | 160 | 20 | 0,25 |

| DKB-M-3-160-50-U1 | 3 | 160 | 50 | 0,37 |

| DKB-M-5-160-50-U1 | 5 | 160 | 50 | 0,37 |

| DKB-M-7-160-50-U1 | 7 | 160 | 50 | 0,37 |

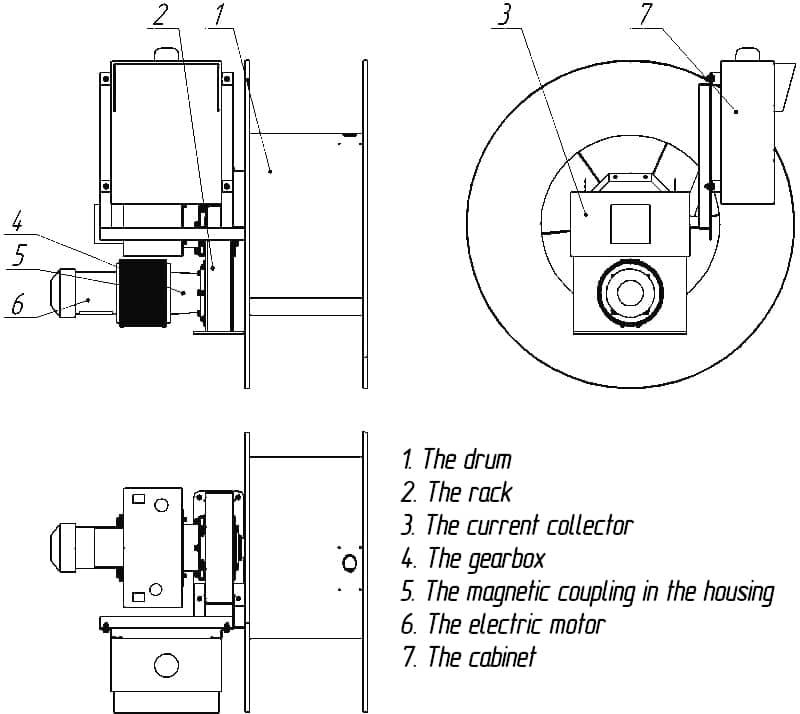

The cable drum 1 is made of sheet steel and is rigidly fixed on the shaft rotating in the bearings of the rack 2, fixed on a metal structure of a power consumer or on a fixed support. The drive of rotation of the shaft with the drum is carried out from the electric motor 6 through the magnetic coupling located in the housing 5, the gearbox 4 and the final gear train located in the rack 2. The cable is connected through the current collector 3 and the cabinet 7. The cable passes in the shaft cavity from the current collector to the drum.

The drum is equipped with an asynchronous magnetic coupling based on permanent magnets (the technology is patented), installed between the electric motor and the drive gearbox. The drum motor always rotates in the same direction, corresponding to the direction of rotation of the drum when winding the cable, and the magnetic coupling transmits torque to the drum drive gearbox. The drum drive always provides the required cable tension by means of the the magnetic coupling slipping, regardless of the direction of movement of the electricity consumer and its speed (if the speed of movement is within the limits specified by the technical characteristics of the drum). The required force is set by adjustment. When using a magnetic coupling, the drum does not need to be reversed. When the feeding point is located in the middle of the path, the drum winds the cable when moving to the feeding point, and when moving from it, unwinding occurs under the influence of the cable tension.

A similar principle of operation of the drum can be obtained using a friction, however, it has a very significant flaw - rapid wearing due to constant mechanical friction during discs flipping. The magnetic coupling doesn't have the flaw, since the leading and driven half couplings do not have mechanical contact with each other.Therefore, the asynchronous magnetic coupling based on permanent magnets has a longer service life, and does not require repair and maintenance.

3

160

10

0,1

5

160

20

0,25

3

160

20

0,25

3

160

50

0,37